Failure Prediction in the Context of Industry 4.0

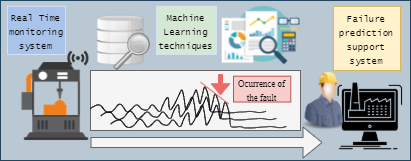

In the era of Industry 4.0, Machine Learning (ML) technologies are viewed as the main potential tools for analysing the huge amount of data collected by industries and predict possible machinery breaks or failures.

The advancements in digital systems and Machine Learning (ML) technologies has paved the way for the collection and analysis of massive data in many fields of knowledge: Energy sector, Health, Economics and Finance, Industry, among others. Regarding the industrial sector, the emergence of new manufacturing paradigms such as Industry 4.0 have led to many industries and companies to start employing these powerful techniques to extract valuable knowledge from the measured data.

One of the main challenges is to predict failures in the industrial processes, such as machinery breakages or manufacturing production stoppages. The economic consequences of these failures can result in loss of millions of euros. Therefore, the prediction of these failures is crucial for avoiding the occurrence of their negative consequences, such as lower quality of the final product, economic losses or safety and environmental risks.

In this context, the analysis of Time Series data (TS) is still a challenge for researchers in a wide range of applications and tasks. Specifically, the continuous monitoring of industrial process variables over time enable the detection of anomalies and accurately anticipate to possible failures. In fact, Anomaly Detection (AD) is one of the most extended ML tasks for detecting abnormal behaviours in TS data and its application in Industry 4.0 is of utmost importance. Note that in the literature, three different types of anomalies are distinguished [1]:

- Point anomaly that refers to points that deviate significantly from the rest of data.

- Collective anomaly related to a set of instances that exhibits an anomalous behaviour compared to the other groups of instances in the dataset.

- Contextual anomaly that refers to anomalous points concerning their environment.

Actually, the common procedure in the majority of industrial application cases starts from creating an experimental database with the behaviour of the process variables (previously selected by domain experts) associated to N failure cases. Therefore, the corresponding patterns for each failure case are obtained and a rule-based algorithm is designed and developed to provide a real-time detection of such anomalies’ patterns [2-4]. However, the process is too tedious and time-consuming, needs expert knowledge support and depends on the available data and failure information.

Therefore, thorough the last decades, research has been focused on the development of different rule-based heuristic ML models able to provide a valid solution for the problem with a lower computational cost and a reasonable time [5]. Nevertheless, the proposed AD solutions are too problem specific and need for a high level of parametrisation. In order to overcome this issue, authors in [5-7] propose different meta-heuristic approaches to provide general approaches applicable to wide domains. However, they are mostly developed for a particular problem and their generalization is complicated.

In the last years, Hyper-heuristic has arisen as a powerful ML technique for intelligently choosing the right heuristic and its parameters or components in each situation [8]. Actually, Hyper-heuristics are viewed as an alternative to the meta-heuristics for handling classes of problems rather than just one particular problem [9]. Therefore, they are a good solution for non-specialized programmers with little knowledge about the problem domain.

Nevertheless, the majority of works in the literature uses a meta-heuristic technique to solve the AD problem. In these cases the prior expert knowledge required about the problem is high and can be provided either in the initial pre-processing steps [10], in the setting of problem parameters such as time-window size, thresholds, etc, or for fixing internal hyper-parameters without which the AD system could not properly work [11-13].

Unfortunately, little research has been devoted to fully implement ML methods that optimize the parameters of the problem making it less dependent on expert knowledge. Authors in [14] develop a methodology for comparing different meta-heuristic methods in the search of the optimal solution, directly optimising the parameters of the problem. However, they employ default hyper-parameters which may lead the meta-heuristic not to reach the optimal solution.

Future directions in the field of AD in Industry 4.0 should be focused on the development of hyper-heuristic approaches capable to automatically identify significant parameters of the TS that enable to anticipate possible failures in industrial processes. The potential of these solutions will be:

- low level of expert-knowledge required,

- an easy-to-use computer system,

- capability to operate over different types of failure problems.

Author:

Diana Manjarrés, PhD Information Technology

Tecnalia, Basque Research & Technology Alliance (BRTA)

References:

[1] Chandola, V., Banerjee, A., & Kumar, V. (2009). Anomaly detection: A survey. ACM computing surveys (CSUR), 41, 1-58.

[2] Hage, R.-M., Hage, I., Ghnatios, C., Jawahir, I., & Hamade, R. (2019). Optimized tabu search estimation of wear characteristics and cutting forces in compact core drilling of basalt rock using pcd tool inserts. Computers & Industrial Engineering, 136 , 477-493.

[3] Hatami-Marbini, A., Sajadi, S. M., & Malekpour, H. (2020). Optimal control and simulation for production planning of network failure-prone manufacturing systems with perishable goods. Computers & Industrial Engineering, 146, 106614.

[4] Lee, W. J., Mendis, G. P., Triebe, M. J., & Sutherland, J. W. (2020). Monitoring of a machining process using kernel principal component analysis and kernel density estimation. Journal of Intelligent Manufacturing, 31, 1175-1189.

[5] Gandomi, A. H., Yang, X.-S., Talatahari, S., & Alavi, A. H. (2013). Metaheuristic applications in structures and infrastructures. Newnes.

[6] Diaz-Cortes, M. A., Cuevas, E., Galvez, J., & Camarena, O. (2017). A new metaheuristic optimization methodology based on fuzzy logic. Applied Soft Computing, 61, 549-569.

[7] Ozcan, E., Bilgin, B., & Korkmaz, E. E. (2008). A comprehensive analysis of hyper-heuristics. Intelligent data analysis, 12, 3-23.

[8] Swiercz, A. (2017). Hyper-heuristics and metaheuristics for selected bio-inspired combinatorial optimization problems. Heuristics and Hyper-Heuristics-Principles and Applications

[9] Liu, D., Alippi, C., Zhao, D., & Zhang, H. (2014). Frontiers of intelligent control and information processing.

[10] Lu, W., Li, Y., Cheng, Y., Meng, D., Liang, B., & Zhou, P. (2018). Early fault detection approach with deep architectures. IEEE Transactions on Instrumentation and Measurement, 67, 1679-1689.

[11] Cai, H., Feng, J., Moyne, J., Iskandar, J., Armacost, M., Li, F., & Lee, J. (2020). A framework for semi-automated fault detection configuration with automated feature extraction and limits setting. In 2020 31st Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), 1-6.

[12] Calabrese, F., Regattieri, A., Botti, L., Mora, C., & Galizia, F. G. (2020). Unsupervised fault detection and prediction of remaining useful life for online prognostic health management of mechanical systems. Applied Sciences, 10, 4120.

[13] Carino, J. A., Delgado-Prieto, M., Iglesias, J. A., Sanchis, A., Zurita, D., Millan, M., Redondo, J. A. O., & Romero-Troncoso, R. (2018). Fault detection and identification methodology under an incremental learning framework applied to industrial machinery. IEEE access, 6, 49755-49766.

[14] Dalla Vedova, M., Berri, P. C., & Re, S. (2019). A comparison of bio-inspired meta-heuristic algorithms for aircraft actuator prognostics. In Proceedings of the 29th European Safety and Reliability Conference, Hannover, Germany, 22-26.